R&D

① Property

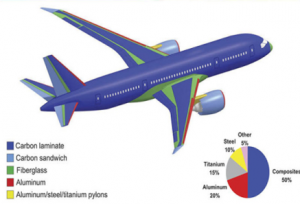

- Worldwide fuel and environmental regulations, light transport is being carried out.

- Development of new materials for low cost, high strength, lightweight material development is essential

- Al matrix composite materials have excellent strength, thermal conductivity and wear resistance depending on the type of reinforcement.

Energy saving policy – lightweight of automobile and aircraft

② Section of Al matrix composite material

- Al-Carbon materials (CNT, Graphene)

- Al-Ceramic materials (Oxide-TiO2)

- Al-Ceramic materials (Nitride-AIN)

- Al-Ceramic materials (Carbide-SiC)

③ Application of Al matrix composite material

- Electronic packaging material of high radiant heat

- Transfer machine engine components

- Automotive brake components

- Transfer machine application component of high capacity

2. A field of study Al-matrix composite material

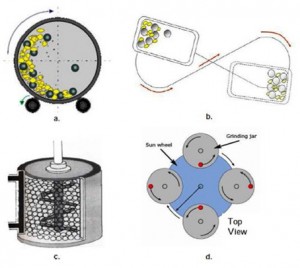

① Mechanical alloying

- Definition

– The process of mechanical alloying consists of repeated flattening, fracture, and re-welding of the powder particles in a high-energy. The result is producing powder of homogenous and fine alloy. - Property

– The speed of revolution, volume and size of charging ball, charging ratio of ball and powder, reaction atmosphere and time are greatly influenced by the ultimate alloy characteristic and properties - Method

– Aluminum scrap and ceramic material to planetary miller for a period of time after feeding (Able to gain powder like images)

Various mechanical alloying

Planetary Mill(Headquarters possession)

Al matrix composite powder

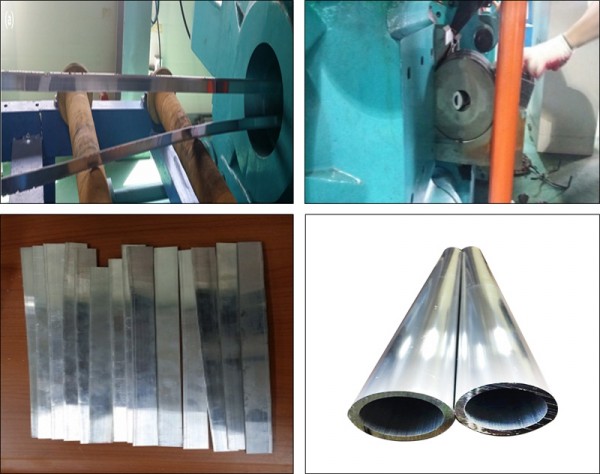

② Vacuum Hot Press

- Definition

– A method to compress the aluminium into a partially melting state and make it into a solid mixture - Necessity

– Aluminum powder is very difficult to densification through the grain boundary diffusion and the formation of liquefied.

– The alumina oxidizing layer formed on the surface of the powder is very stable. Therefore , it is difficult to remove from the usual reduction atmosphere.

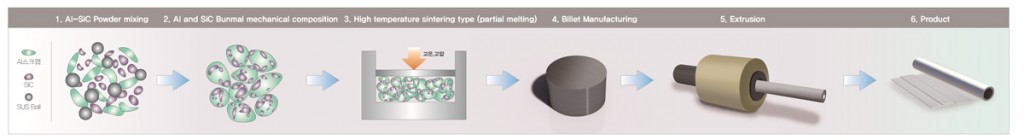

– To overcome diffficult sinterability of the aluminium powder, the headquarters used high-temperature sintering compression to manufacture composite materials billet. - Method

– The resultant of Al matrix composite powder is charged the vacuum hot press, after heat the specified temperature and proceed with pressing and sintering.

50 ton vacuum hot press

(Hydraulic pressure)

25 ton vacuum hot press

(Hydraulic-Pneumatic pressure buster)

Production method and products of Al matrix composite material

③ Other manufacture process (Atomizing, Cast process …etc)

④ Process schematic diagram of Al matrix composite material

3. Organizational and characteristic analysis of Al matrix composite material

① Organizational analysis of Al matrix composite material

- Anlaysis

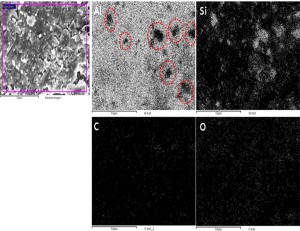

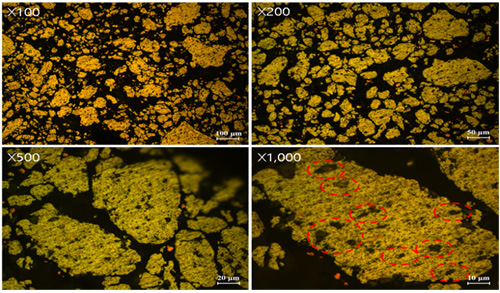

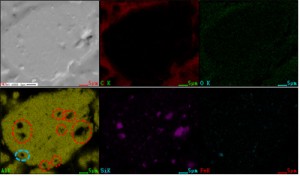

– EDX results of Al matrix composite powder surface : Verifty uniform distribution of ceramic within Al matrix

– EDX results of Al matrix composite powder cross section : Verifty uniform distribution of ceramic within Al matrix - Result

– Verify of Al matrix composite powder making successful

– Possibility of application to other ceramic materials later

OM images of Al matrix composite powder surface

SEM EDX images of Al matrix composite powder surface

SEM EDX images of Al matrix composite powder cross section)

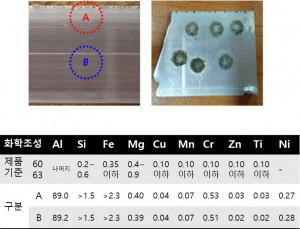

② Characteristic analysis of Al matrix composite material

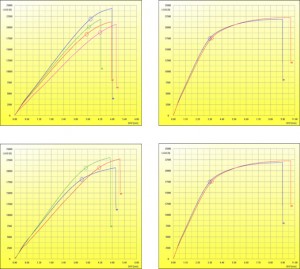

a. Tensile strength and elongation

– Tensile strength : average 400 MPa

– Elongation : average 5 %

b. Chemical component analysis

※ Please contact our main office (063-263-2579) for further information